PVC/CPVC/PP True Union Ball Valves

Product

Item-Name:

Specification:

Color : PVC(Dark Grey), CPVC(Light Grey), CLEAR PVC(Clear)

PP(Nature)

ITEM NO: SL-640

Specification:ITEM NO: SL-640

Size: 1/2" - 4"

Material:PVC,CPVC,Clear PVC, PP, PVDF

Joint End : Socket: ( ANSI, JIS, CNS, DIN);

Threaded: (NPT, BSPT, BSPF);

Flanged: ( 10K, 150LB)

Working Pressure:150PSI

Operation Temperature : PVC(0~55℃); CPVC&PP(0~95℃)Color : PVC(Dark Grey), CPVC(Light Grey), CLEAR PVC(Clear)

PP(Nature)

ADVANTAGES:

- 1.USA NSF approved & materials meet drinking water standard

- 2.Smooth opening & closing thanks to a lower torque

- 3.100% pure virgin material, CaCO3 free (Chalk)

- 4.UV resistant powder added

- 5.100% pressure testing before leaving the factory

- 6.Can be assembled with Pneumatic/Electtric Actuators

More-Details:

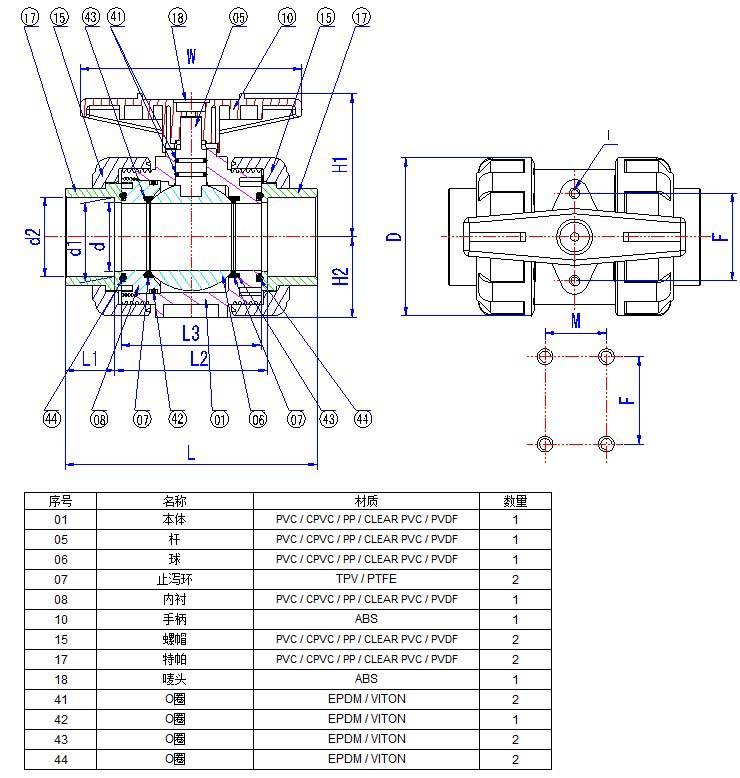

单位: MM

| SIZE | d | d1 | d2 | D | L | L1 | L2 | L3 | W | H1 | H2 | F | M | I | operating torque (Nm) | ||||||||

| ANSI | DIN | JIS | CNS | ANSI | DIN | JIS | CNS | ANSI /JIS /CNS | DIN | ANSI /JIS /CNS | DIN | ||||||||||||

| 1/2"(15) | 15 | 21.54 | 20.30 | 22.30 | 22.40 | 21.23 | 20.10 | 21.70 | 21.90 | 54.00 | 104.80 | 92.00 | 22.30 | 16.00 | 60.00 | 52.00 | 84.00 | 52.50 | 27.50 | 31.00 | — | M6 | 2.0 |

| 3/4"(20) | 20 | 26.87 | 25.30 | 26.30 | 26.40 | 26.57 | 25.10 | 25.70 | 25.90 | 63.00 | 113.00 | 100.00 | 25.50 | 19.00 | 62.00 | 54.00 | 90.00 | 59.00 | 32.00 | 33.00 | — | M6 | 2.5 |

| 1"(25) | 25 | 33.65 | 32.30 | 32.33 | 34.50 | 33.27 | 32.10 | 31.67 | 33.90 | 73.50 | 127.20 | 114.00 | 28.60 | 22.00 | 70.00 | 62.00 | 106.00 | 67.50 | 37.25 | 40.00 | — | M6 | 4.0 |

| 1 1/4"(32) | 32 | 42.42 | 40.30 | 38.43 | 42.50 | 42.04 | 40.10 | 37.57 | 41.90 | 84.50 | 142.00 | 130.00 | 32.00 | 26.00 | 78.00 | 70.00 | 116.00 | 77.50 | 42.75 | 52.00 | — | M8 | 5.0 |

| 1 1/2"(40) | 40 | 48.56 | 50.30 | 48.46 | 48.60 | 48.11 | 50.10 | 47.54 | 47.90 | 98.00 | 157.50 | 151.50 | 35.00 | 32.00 | 87.50 | 79.50 | 128.00 | 90.00 | 50.00 | 52.00 | — | M8 | 7.5 |

| 2"(50) | 50 | 60.63 | 63.30 | 60.56 | 60.60 | 60.17 | 63.10 | 59.44 | 59.90 | 118.00 | 171.00 | 38.00 | 95.00 | 85.00 | 140.00 | 106.00 | 60.00 | 70.00 | — | M8 | 8.5 | ||

| 2 1/2"(65) | 63 | 73.38 | 75.30 | 76.60 | 76.70 | 72.85 | 75.10 | 75.87 | 75.90 | 150.00 | 238.50 | 47.00 | 144.50 | 132.50 | 210.00 | 136.50 | 76.50 | 84.00 | 45.00 | M10 | 13 | ||

| 3"(80) | 75 | 89.31 | 90.40 | 89.60 | 89.70 | 88.70 | 90.10 | 88.83 | 88.90 | 169.00 | 268.00 | 51.00 | 166.00 | 150.00 | 235.00 | 149.50 | 86.00 | 84.00 | 45.00 | M10 | 16 | ||

| 4"(100) | 97 | 114.76 | 110.40 | 114.70 | 115.00 | 114.10 | 110.10 | 113.98 | 113.80 | 211.00 | |||||||||||||

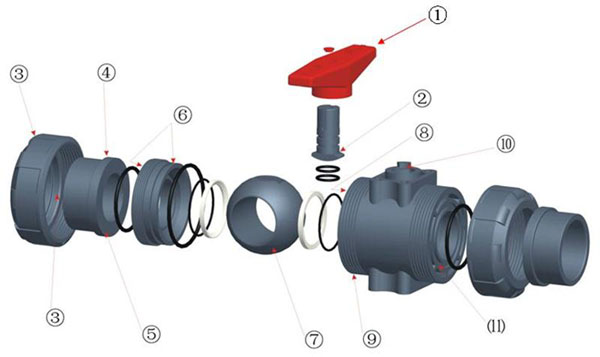

- 1.Underside handle extends the length so that both OFF block will not be exposed, more beautiful

- 2.Extrusive circular plane change to both side plane, easy processing and assemble

- 3.Lateral plane and ribs of the Union Cap, from the right-angle change to incline to increase the intensity

- 4.Union end from right-angle to slope increase in a round protruding rib to increase the intensity

- 5.Surface of Oring change to a plane, and each have been cutting lathe in order to ensure its flatness

- 6.Seal carrier and Oring slot is processed by machine, sealing performance is improved.

- 7.Each ball has increased turning and grinding to ensure that its true roundness and smoothness. So much easier to handle and not easy leak

- 8.Inside body is processed via CNC machine to make sure acurate dimensions

- 9.Increase the slope of trapezoidal teeth and the number of teeth in order to ensure their connection strength

- 10.Through hole is processed via CNC machine to make sure the stability of sealing

- 11.Slot dimension is improved, sealing performance is strengthened.

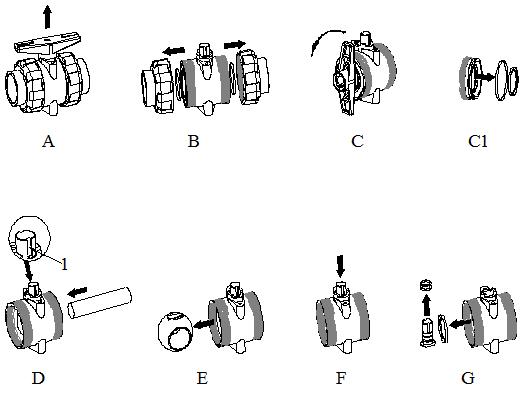

- DISASSEMBLY DETAILS:

A - pull out the handle

B - take apart the nuts

C - turn the seal carrier in an anticlockwise direction

C1 - take out the Seat & Oring

D - push the ball

E - pick out the ball

F - press the shaft

G - pick out the Seat & Oring

Note:

- For abvoe "D" step, pls take note the groove position "1" on the shaft

- To assemble the valve, pls follow up the steps from "G" to "A"